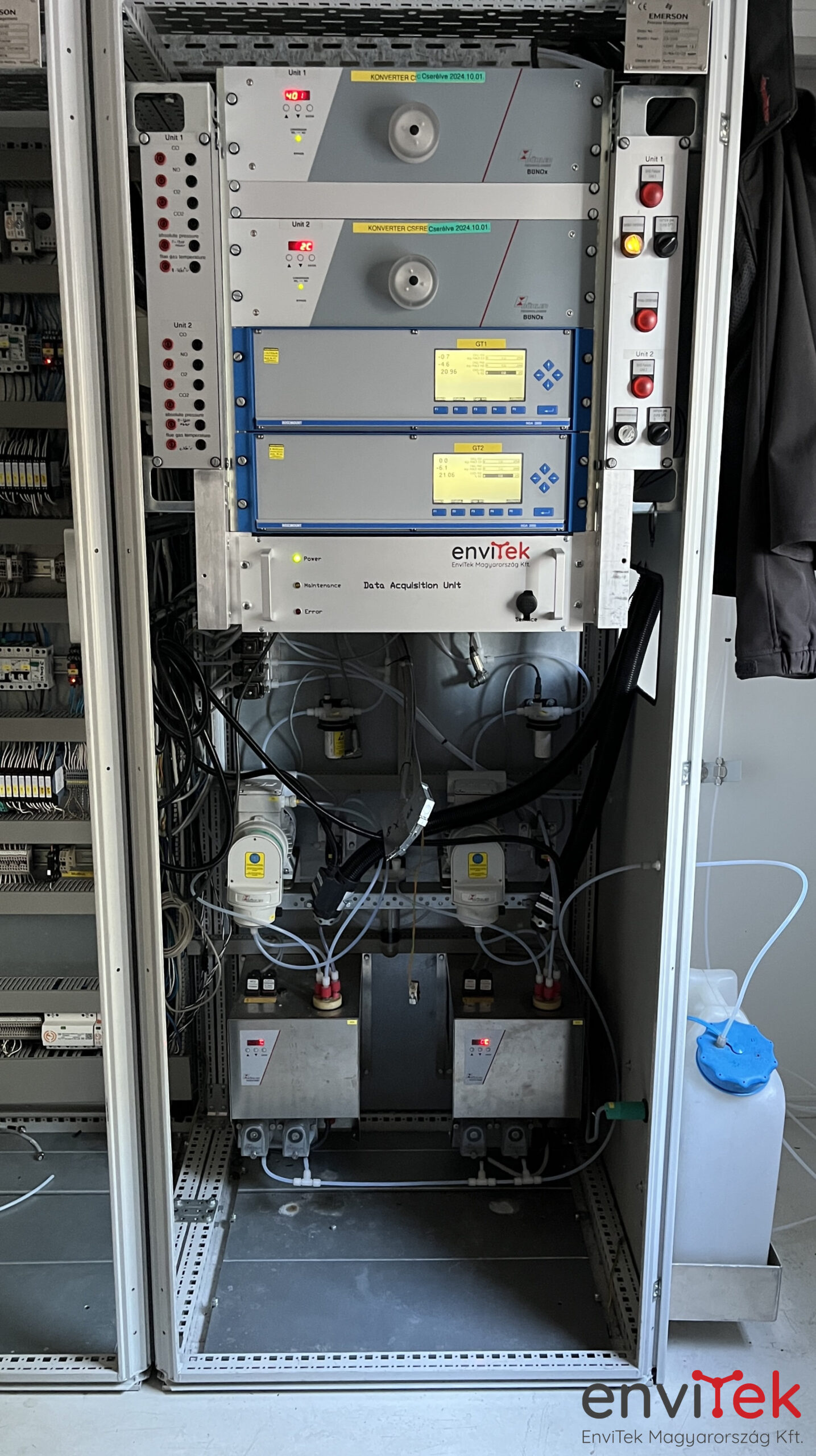

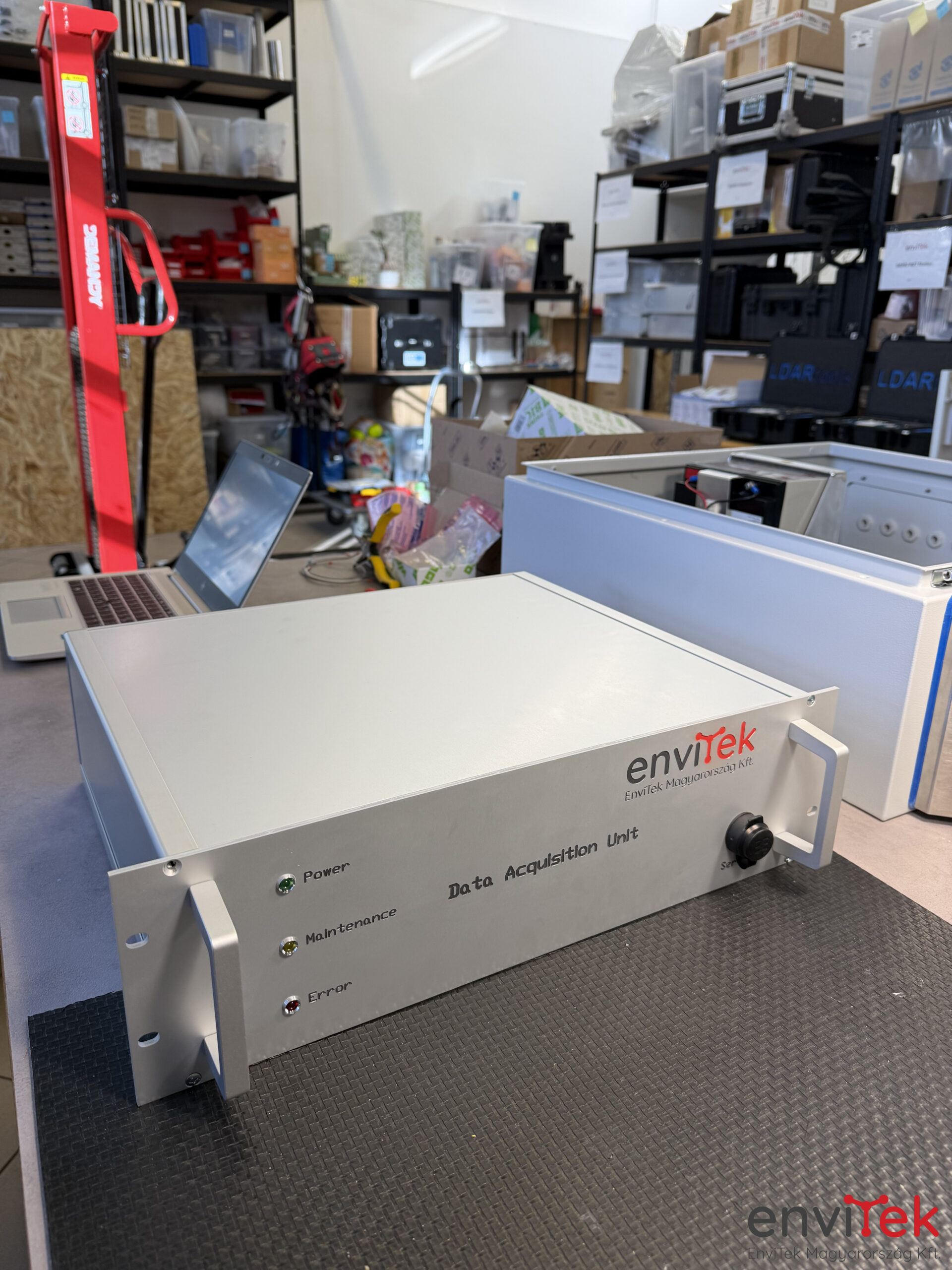

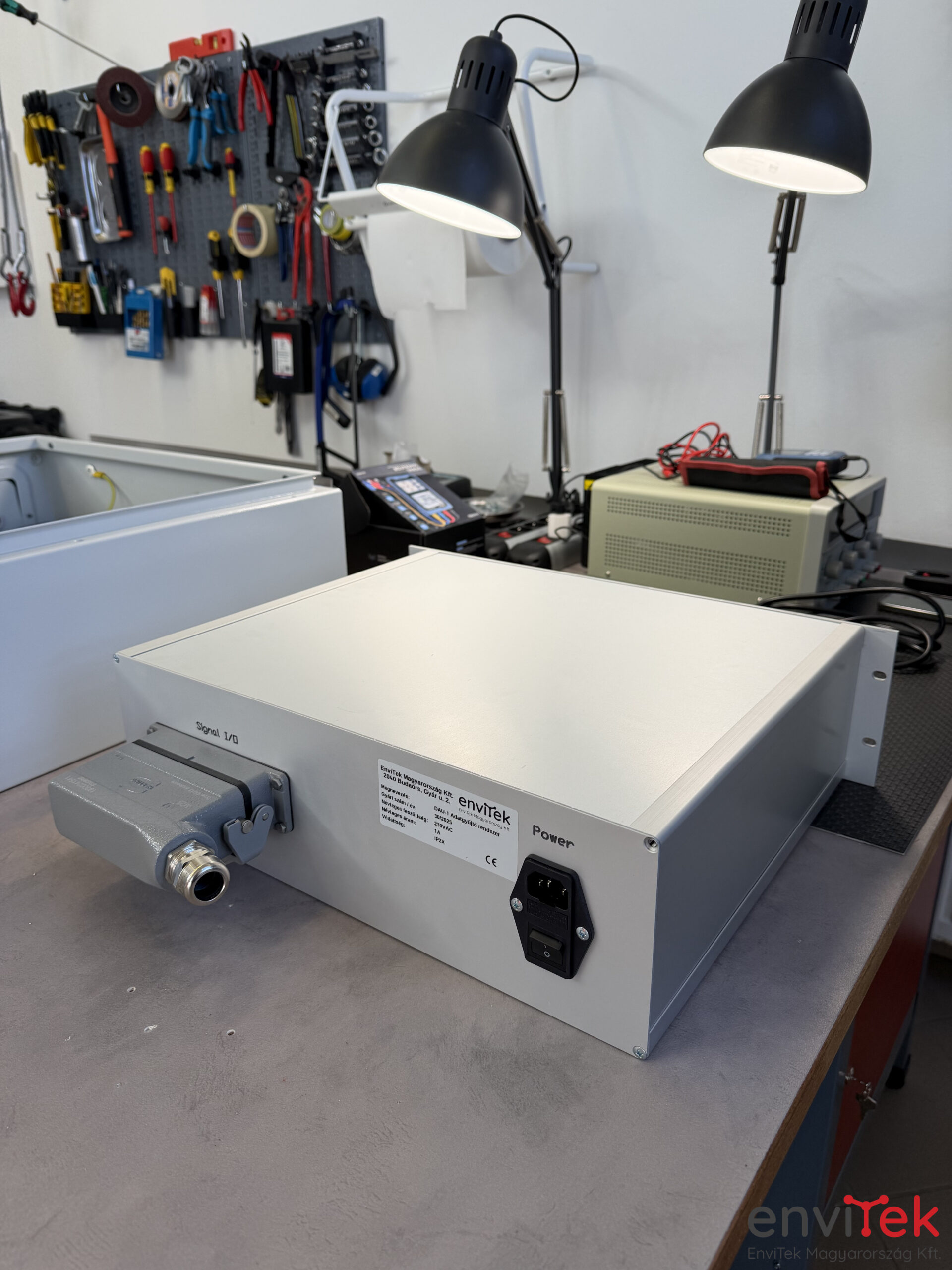

In November, we implemented the retrofit of the data acquisition system of a domestic 116MW GT power plant (2 pcs 58MW nominal electrical capacity). The manufacturer’s support for the DURAG D-EMS 2000 emission data collection and reporting software, installed in the early 2000s and used with satisfaction until now, has been discontinued, so our partner opted for the new D-EMS 2020 software. During the project, it was a requirement that the emission container should not be expanded with a new wall-mounted electrical distribution cabinet, so we integrated the new DURAG system into a 19” rack 3U high cabinet of our own design and manufacture.

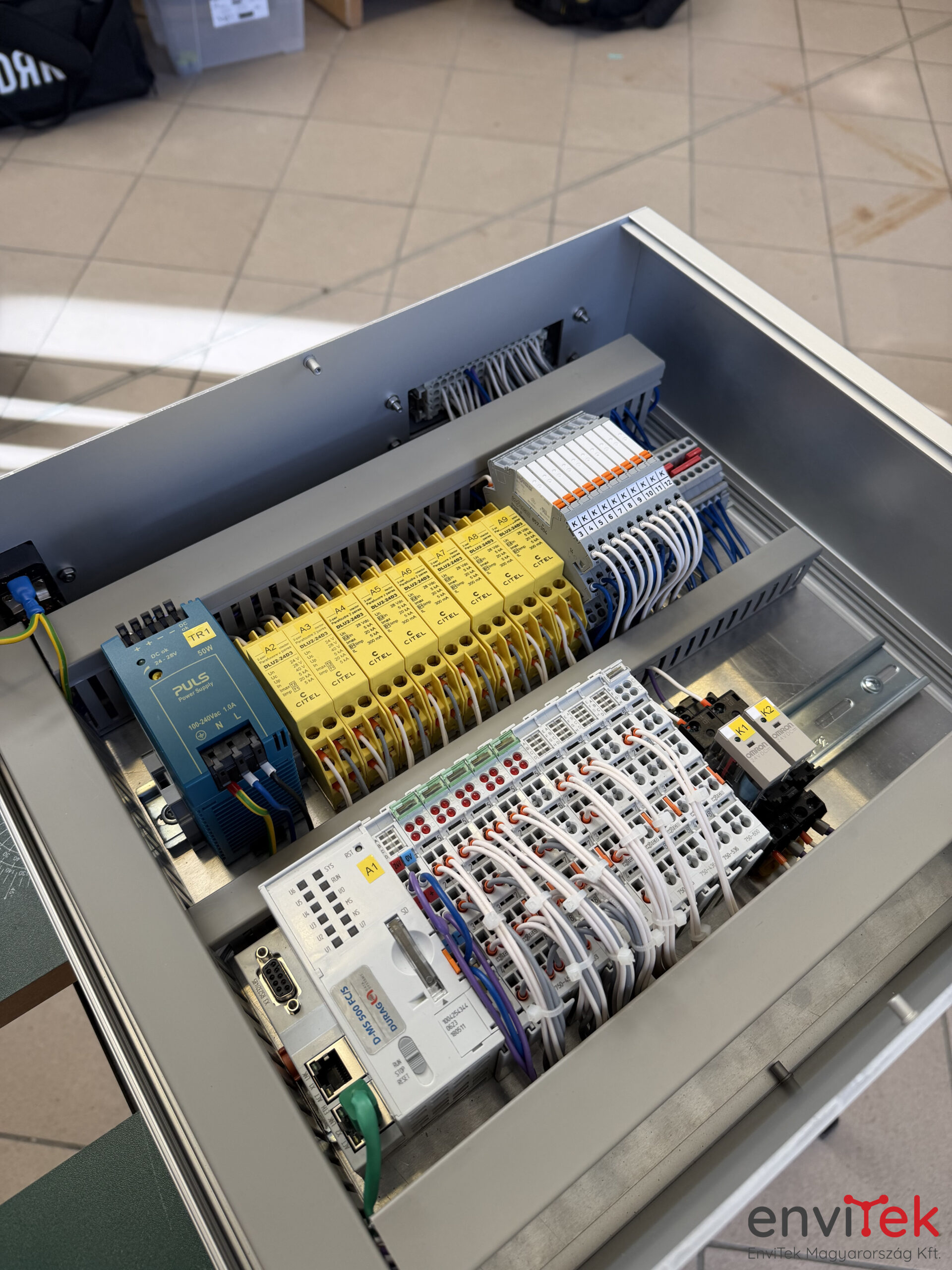

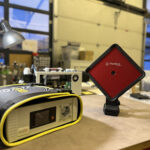

The 8 4-20 analog mA signals and 5 digital contacts arriving from each boiler line arrive in the electrical distribution part of the emission cabinet after separation at terminal block level. Our design and construction interface started from here, from here we fitted the integrated DURAG D-MS 500 FC/S data acquisition unit with a new communication signal cable, which communicates with the emission server PC in the server room via an Ethernet connection. In order to ensure proper process control, we also installed a client license in the same network in the DCS control room.

The DURAG D-EMS 2020 data acquisition and reporting system has been tested and certified by TÜV according to parts 1-3 of the DIN EN 17255 standard, thus ensuring “future-proofing” and compliance with increasingly stringent regulatory requirements.