In February 2025, a Hungarian company producing special chemical products expressed interest in the fact that during the commissioning of their new plant, leak testing of the plant’s detachable joints and technological connections was extremely slow and difficult.

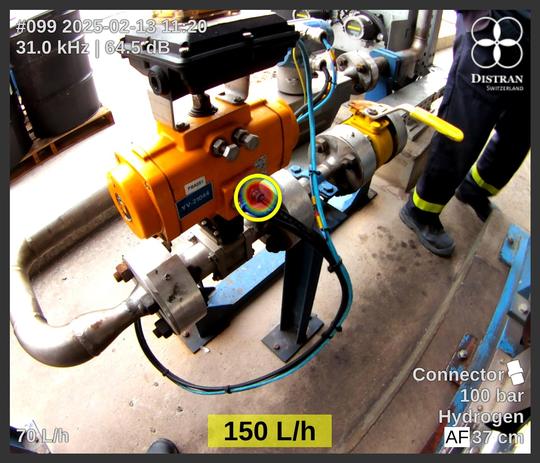

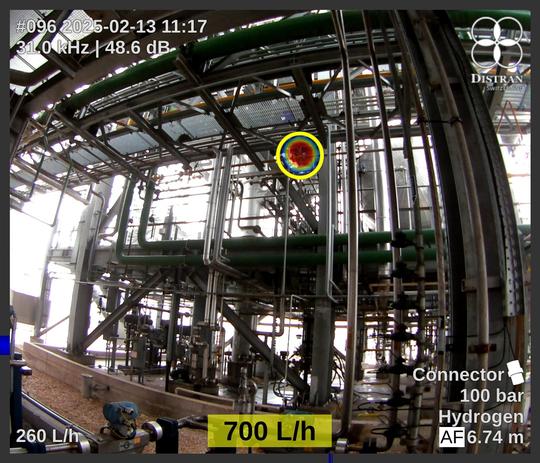

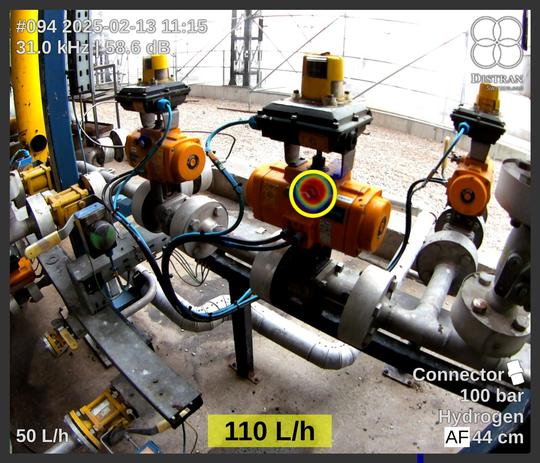

To speed up the process, we recommended the Distran (Switzerland) Ultra Pro X ATEX Zone 2 certified acoustic camera, which operates similarly to the human ear. When the medium exits the pressurized system, the escaping gas generates ultrasound due to the pressure difference. The acoustic camera can process this ultrasound signal with its 124 microphones and overlap it with the image generated by the built-in optical camera, showing the exact location of the leak and, if set correctly, the size of the leak.

After the task was agreed upon by phone, we discussed the camera’s operating principle, advantages, and limitations of applicability during a short presentation on site, and then the field measurement began.

Upon entering the plant area, we found 10 non-conformities in 30 minutes. Among the identified leaks were H2 leaks during tank truck filling, specific holes in pneumatic connections, compressed air leaks in several areas, pipeline leaks located at high altitudes, and leaks in the equipment used to generate vacuum.

Our on-site demonstration was so convincing that the head of engineering department assured us that the Distran Ultra Pro X instrument was the ideal choice for the fast and accurate execution of their tasks and the continuous development of their technology.

At the end of March 2025, we comissioned our partner’s own acoustic camera.