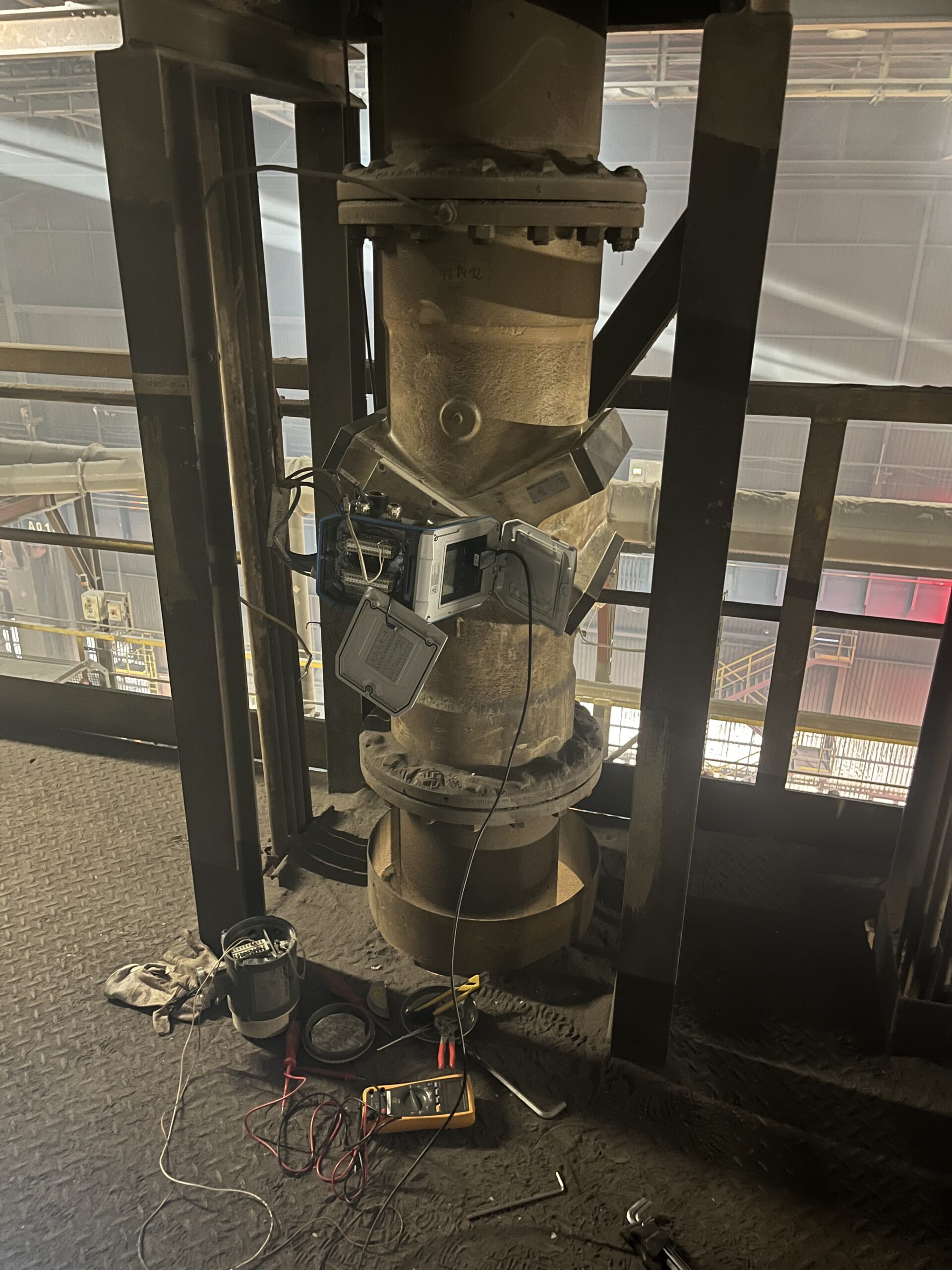

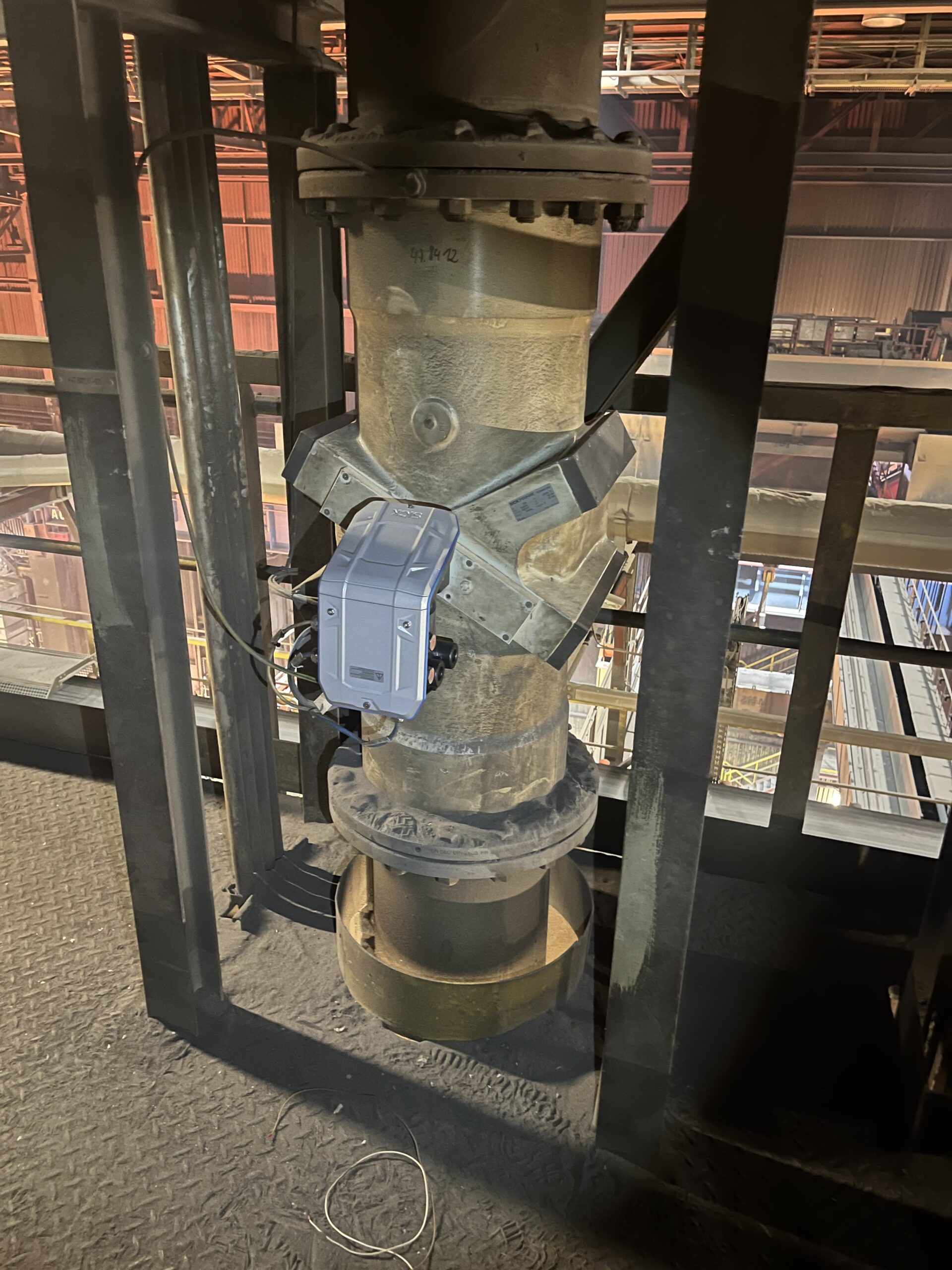

As a subcontractor of the manufacturer, we were asked to perform a gateway upgrade on a DN350 FLOWSIC600 flowmeter installed in 2006 and used for process measurements in Voestalpine steelplant in Linz.

Besides leaving the transducers and the meter body in it’s original state, the work has the following benefits:

• we upgrade the meter with a new SPU (Signal Processing Unit), thereby extending the life of the meter, a new guarantee period will start (on the SPU),extending the MTBF value.

• we can use the new, supported diagnostic software (FLOWgate™), instead of the outdated, unsupported MEPAFLOW600 CBM,

• we equip the meter with new and more I/Os (1xEthernet, 3XRS485).

During the work we did the following:

• data backup was performed on the old FLOWSIC600 via MEPAFLOW600 CBM software (creation of logbooks, internal parameters, diagnostic and session files),

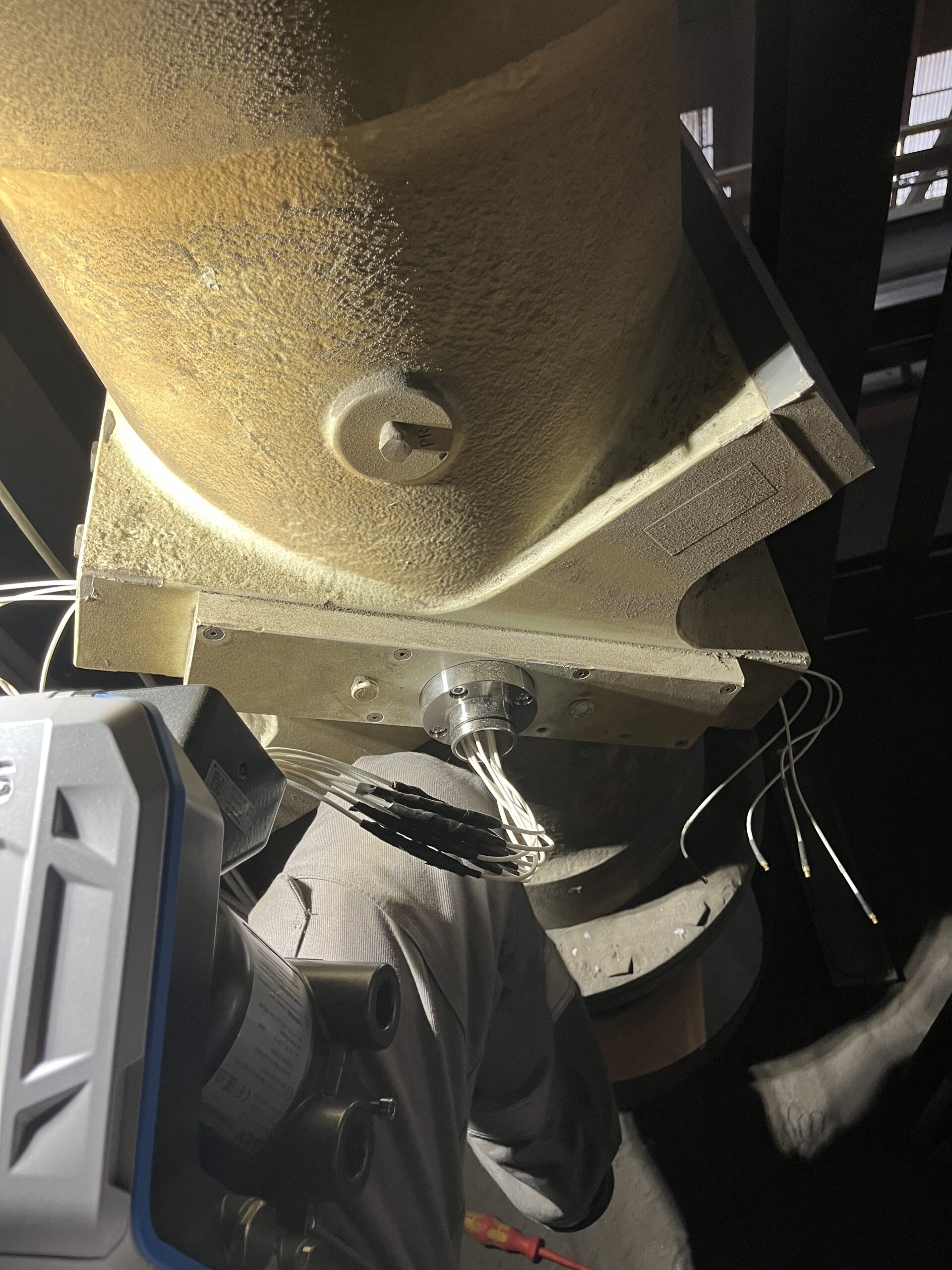

• We dismantled the cover of the ultrasonic transducers, disconnected the coax cables between the old SPU and the measuring transducers,

• we installed a new SPU neck adapter and a new SPU,

• we connected the old measuring heads to the new SPU with self-adhesive glue,

• we imported the parameters of the old meter in FLOWgate™ software tot he upgraded FL600-XT.